In Amoy Wheels,we have the tests standard for our carbon rim production.Usually,we have twelve kinds of tests on our carbon rims.Before each wheel is released it must have to pass all the testings including UCI vertical impact test,additional impact,stiffness,trueness,longevity test,frequency torque fatigue test and tire pressures test.With strict high-quality standards on the manufacturing processes and 100% quality test&check to guarantee all the rims greater than UCI/ISO Test standard.

Test Standards:UCI Vertical Impact Test

The impact resistance test shows the overall

structural performance of the wheels.Impact point

includes air nozzle,45°,90°,180°,270°,315°.The

striker (15.45kg) is dropped from a specific height

above. The higher the striker is raised, the greater

the impact force is.

Test Standards:Lateral Rigidity Test

The lateral rigidity test measures the stiffness or

rigidity of a bicycle rim in the lateral direction,

which is perpendicular to the plane of the wheel.

This test evaluates the performance and safety of

a bicycle wheel, particularly in racing or high-performance applications, where precise handling

and stability are critical.

Test Standards:Spoke Hole Tension Test

This test confirm that the key position around the

holes has been precisely reinforced during the

layup process.The rims are capable of

withstanding a spoke force of more than 300kgf

when hand built which offers better wheel

performance, durability and reliability.

Test Standards:Lateral Vertical Rigidity Test

The test is to predict the behavior of wheels by

precisely measuring the lateral vertical rigidity of a

raw rim. The test shows how well a rim resists

flexing and deforming laterally and vertically.The

stiffness of the rim can affect the responsiveness

of the bike, the control and stability of the ride,

and the transmission of power from the rider to

the road.

Test Standards:Compression Test

Carbon wheel compression test is conducted to

evaluate the ability of carbon wheels to withstand

compression and ensure that they are safe and

durable for use in cycling.The striker weight

120kg and compress rim for two minutes.The rim

deformation <1 mm, rim keeps inact and no

sound vibration.

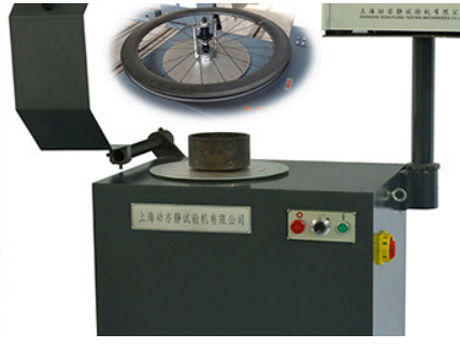

Test Standards:Dynamic Balancing Test

The balance of wheels is very important during

riding.Unbalanced wheels would wobble at high

speed, which undermines the control ability of the

bike.We test the overall dynamic speed balance

of our wheels to make it more stable and higher

performance during riding.

Test Standards:Tire Pressures Test

We inspect the compatibility of rim and tire, the

ease of mounting and disassembly the tire, actual

tire width, and brake track deformation due to

inflation pressure.

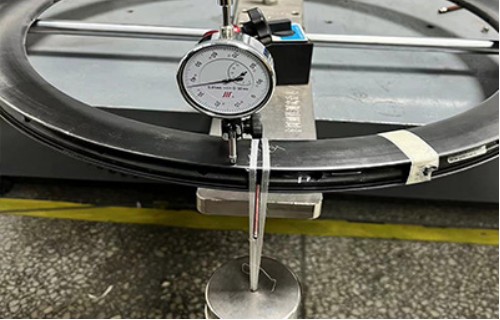

Test Standards:Roundness & FlatnessTest

Assuring rims are accurately flat and round out of

the molds which means greater stability when

assembling the rims into wheels.If the roundness

of rim is imprecise,it would affect the spoke hole

tension and wobble under higher riding speed.

Test Standards:Brake Test

The test evaluates the braking performance and

heat tolerance of the rims.The result would be

affected by factors such as rim shape, brake track

material, and weather conditions.This test can

detect the safety and reliability of wheels during

riding.Braking temperature and braking distance,

were mainly adopted to reflect the qualification.

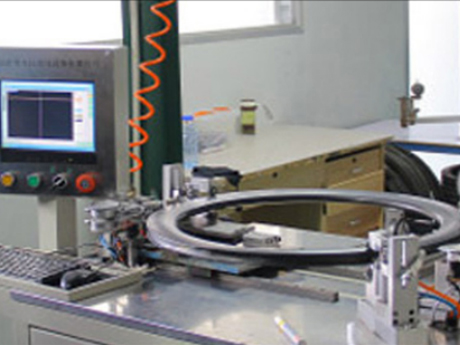

Test Standards:Wheel Building Test

All the defects of rims can be magnified during

wheels building process.If the spoke hole angle is

off,wheels would be wobbled.The wheel is

predictable and within tight tolerances.

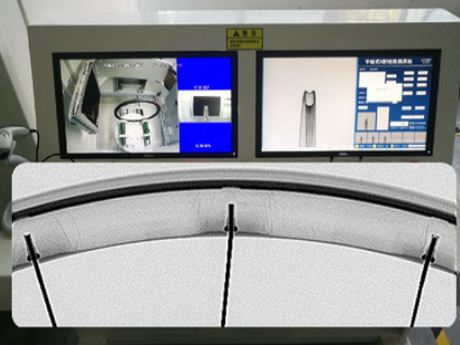

Test Standards:X-ray Test

Through X-ray inspection,we can easily can

detect the abnormal layups,impurities, inner wall

shape, etc.

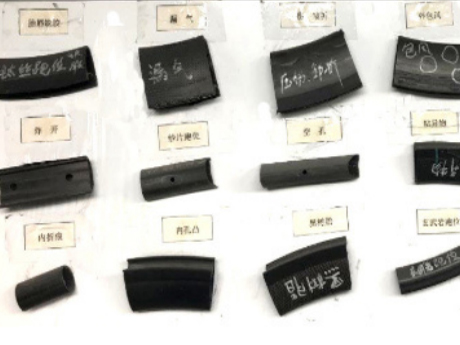

Test Standards:Rim Pieces Inspection

We gather all the rims pieces with quality problem

tto R&D department.Our researchers would

analyse these rim pieces and improve.