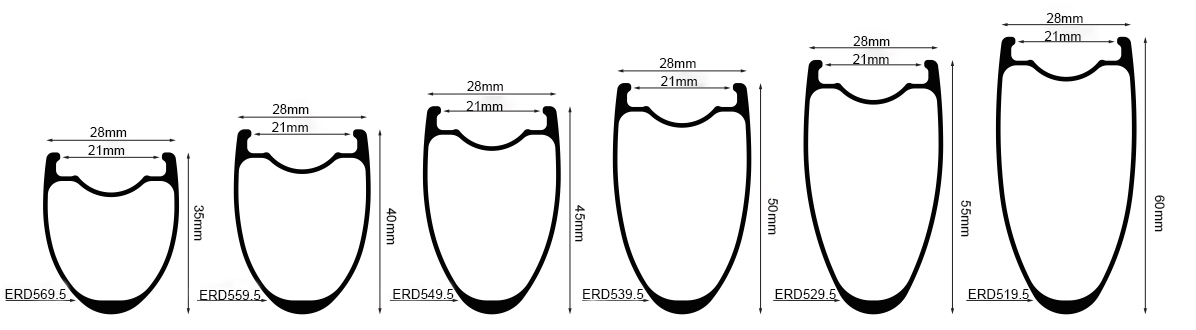

Road Rim Specification

| Model | XDR45 | Tire Type | Clincher/Tubeless |

| Material | Toray T700 & T800 | Rim Weight | 385±15g |

| Rim Size | 700C | Rider Weight Limit | 440lbs/200kg |

| Rim Depth | 45mm | Max Tire Pressure | 150psi |

| Inner Width | 21mm | Max Spoke Tension | 400kgf |

| Outer Width | 28mm | Spoke Hole Angle | ±7° |

| ERD | 549.5mm | Recommend Tire Width | 700*25-43C |

| Rim Bead | Hooked | Warranty | 3 Years |

Customization | Spoke Hole: Hole Count, Spacing, Pattern, Drilling Angle, Diameter | ||

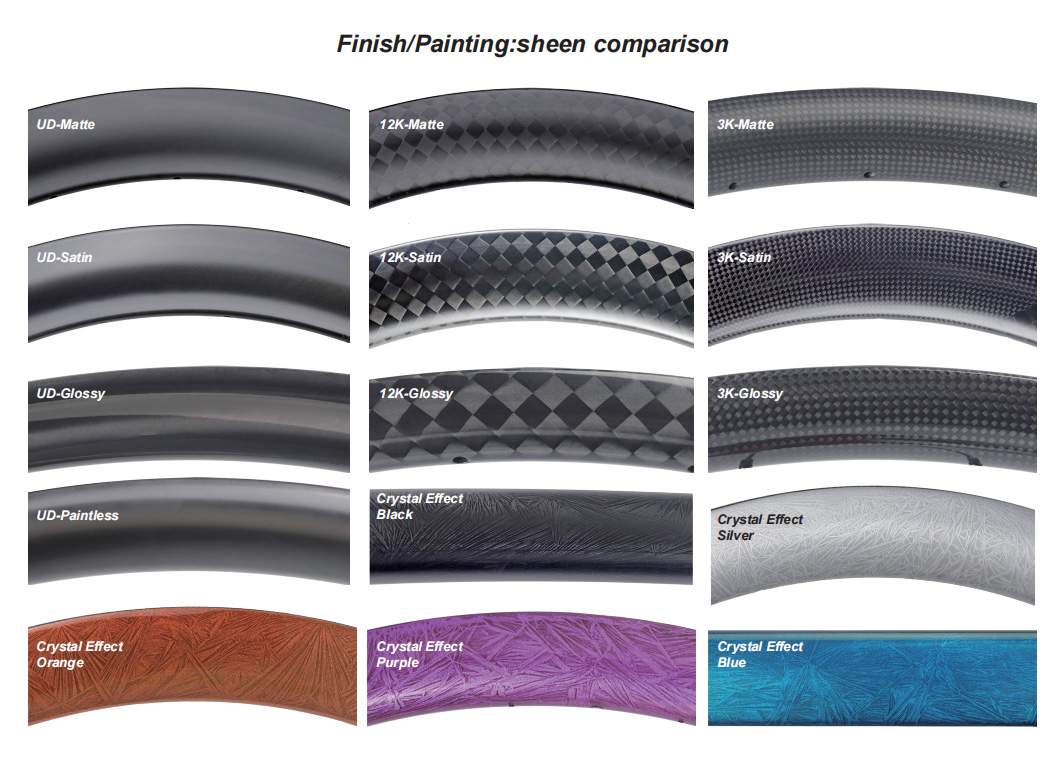

| Finish: Matte, Glossy, Satin, Colored Paint | |||

| Weave: UD, 3K, 12K, others | |||

| Weight Style: Standard,Ultra-Light, Heavy Duty | |||

| Full Customization:Get in touch with us (oem@amoywheels.com) to discuss your customization requests in details. | |||

Road 700C 28mm Width Clincher & Tubeless Ready

High Modulus Reinforcement Strip-Bridge Structural Dynamics

Each AW rim adopts a high modulus carbon reinforcement strip (we called Bridge Structural Dynamics)where the spoke holes are placed to ensure that high tensions are not an issue.

In the meantime through unique architectonics techniques our carbon rims take weight saving and strength to an entirely new level.

All spoke holes are drilled at specific angles to reduce stress on the the spokes and nipples which works well with average hub dimensions.

Material And Manufacturing

We mostly use Toray carbon fiber,especially T700 and rest of T800,T1000 mixed.Both of T800 and T1000 are too rigid to be used alone.We have a unique cutting technology on carbon cloth to balance the strength and rigidity.

Multiple layers of high-tensile carbon sheets are used for Amoy Wheels,this giving the rim a very high strength with sufficient stiffness.

All the carbon rims are tubeless ready and rounded edges to make the tire fiting well.

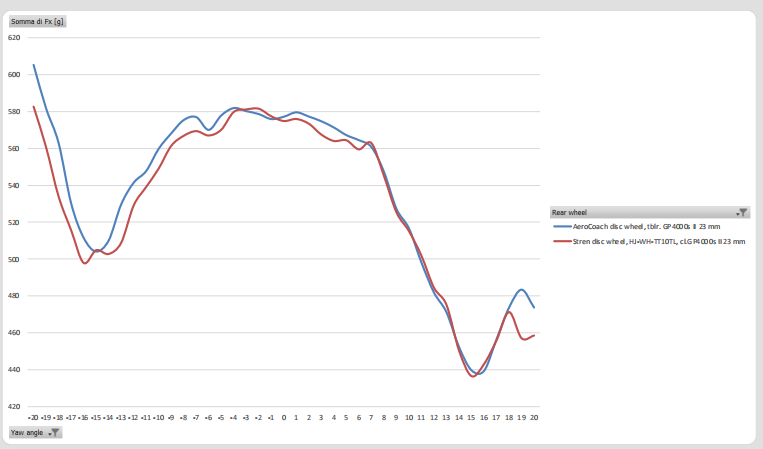

Rim shape design passes through software fluid Analysis to optimize structure so that it has a better wind resistence.Anlyzing the wind resistence with ±20° Angle to optimize the coefficient of the wind resistence.

Strict Quality Control System

During the molding process,heat and pressure are accurately controlled and monitored in the composite curing ovens.Each carbon rim takes almost 30 steps in process and needs 7 days from start to finish.

We have a strict quality check and record in each step.

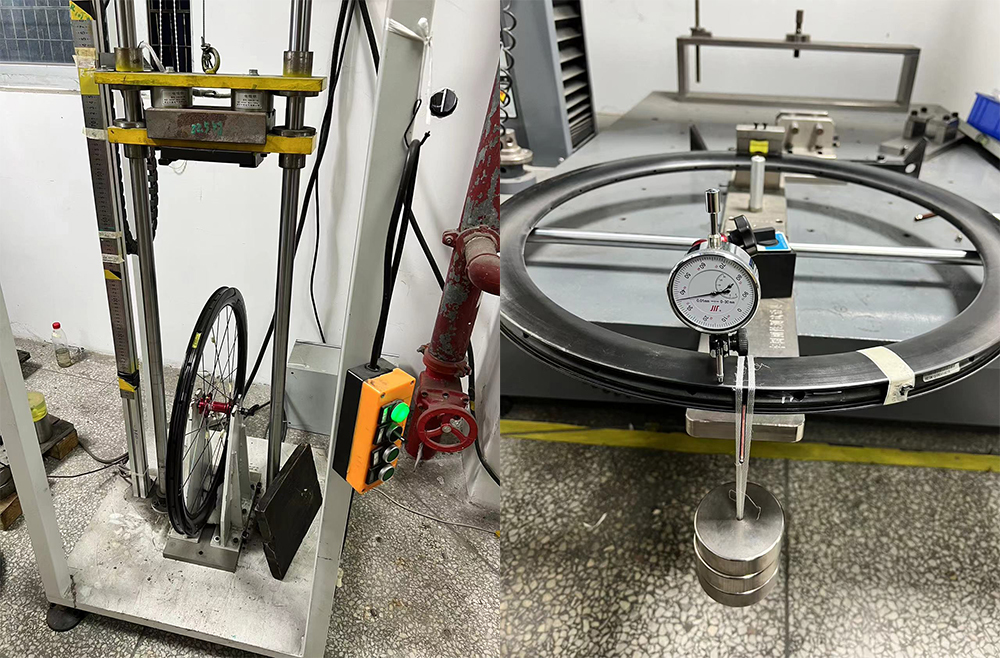

Carbon Rim Tests

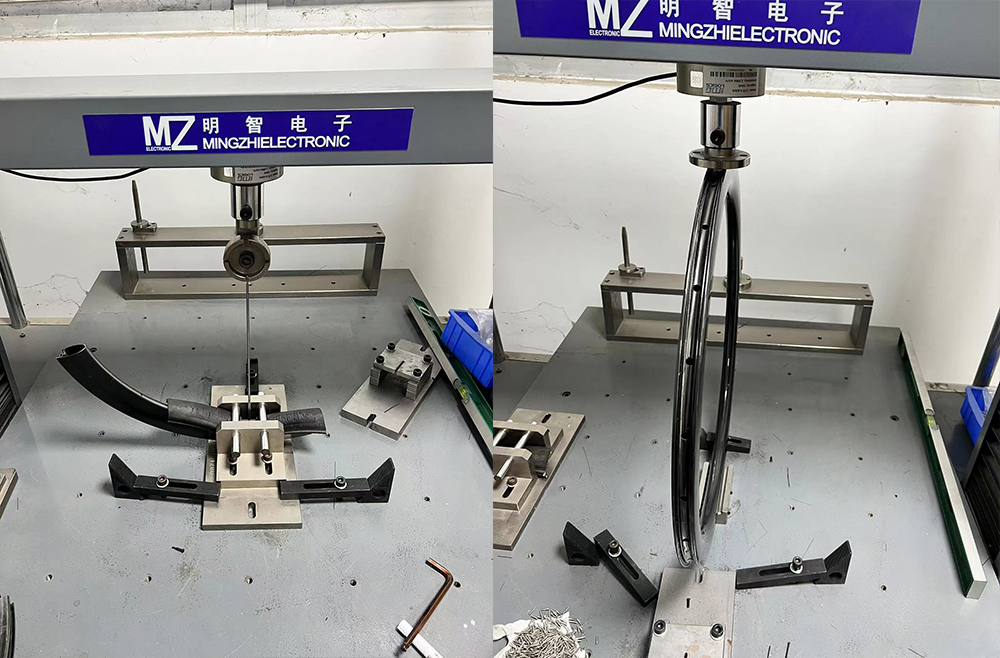

UCI Vertical Impact Test Lateral Rigidity Test

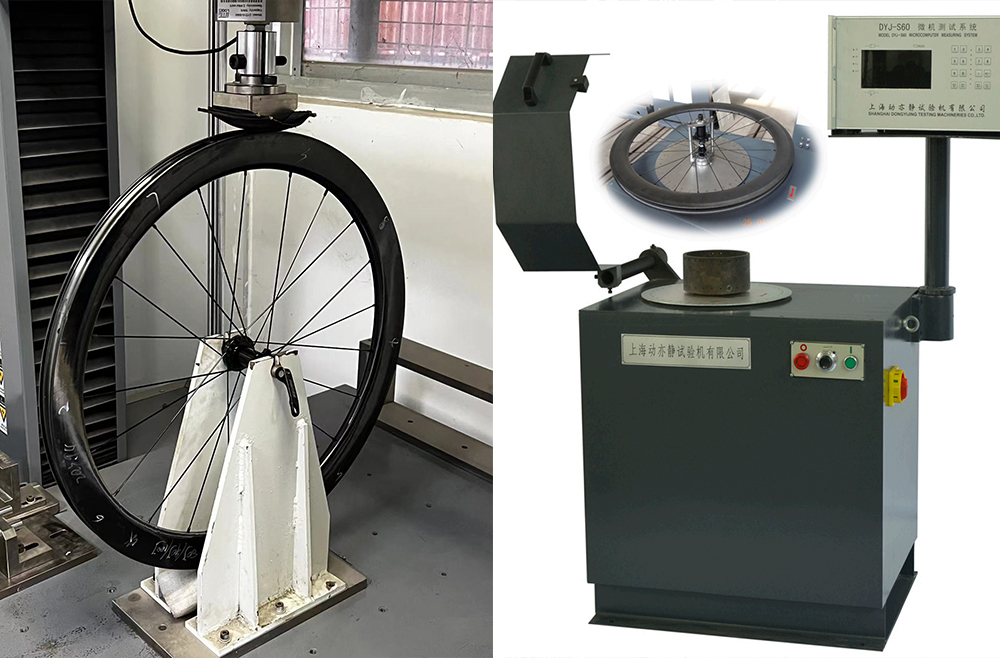

Spoke Hole Tension Test Vertical Rigidity Test

Compression Test Dynamic Balancing Testing

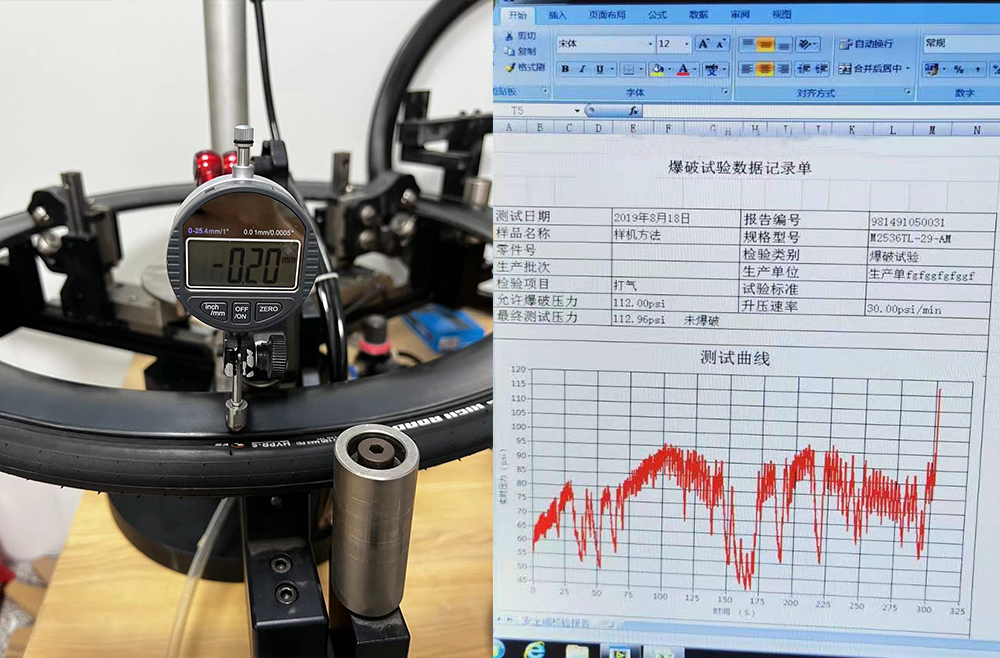

Tire Pressures Test

Our online products list only a portion of our products.Feel free to email us at sales@amoywheels.com,We can talk more details.

If you buy our stock products,there is no quantity requirement.You can send us your logo first and then we will quote you the logo cost upon decal or laser carving.

Generally 7-15 days.The exact lead time depend on the order.

If you want to customize your brand wheels,you can send your inquiry to oem@amoywheels.com. Our sales assistant will offer you the customization service.

Amoy Wheels mainly produce carbon rims and wheels,also produce carbon forks and carbon spokes now.

▪ Customize logo, customize painting, as well as customize packaging (free artwork design). ▪ Develop your own mould carbon rims, or other carbon components (OEM&ODM). ▪ Provide sales advice (based on the market information we get, sales record and customers' feedback, etc). ▪ In-time delivery (with the help of our order and production management system). ▪ 7x24 hours fast service support (both Pre-sale service and After-sale service).

We have more than 25 engineers in our R&D Dept. Some of them have over 15 years experience in carbon rim bicycle industry, plus worked in OE factories for brands of Specialized, Cannondale, Pinarello etc... With the support of experienced R&D Dept., we are always in the leading for new products developing. All of our carbon rims are made of high modulus carbon fiber (Toray T700, T800 and T1000), and they are tested under new ISO4210 standard. In addition, we raise the test standard up to 20% to do stricter testing. We never start mass production until our new products pass all the tests successfully.

Yes! Please email us (sales@amoywheels.com) or leave a comment below if you’d like us to build your hubs to new Amoy Wheels rims.We’ll get back to you to arrange hub shipment, and set up a purchase order ahead of the building process.

From weight to paint, hole count to rim finish, customize it all!

Hookless rims are manufactured without bead hooks, the inward protruding edges at the top of the rim bed that help to retain clincher tires under pressure. The internal rim walls of a hookless rim are flat and straight (and hence also sometimes known as TSS - Tubeless Straight Side).

The key benefits of hookless can be distilled down to the following:Stronger rim construction.Lighter weight rims.Slightly more aerodynamic profile of the global system (rim and tire combined).Lower manufacturing costs, which benefit the rider if they are passed on.

Tire pressures on hookless wheels should not exceed 72.5psi. Please also refer to any additional guidance from the tire manufacturer, and do not exceed the tire's’maximum stated pressure.